FLOW SURVEILLANCE

Optimised fluid transfer from one location to another is a fundamental part of the oil and gas industry

be it from reservoir to wellhead, wellhead to process facility or process facility to export terminal and beyond.

We combine a variety of cutting edge technologies to offer a turnkey flow surveillance system

Our proprietary optical method is non-intrusive and requires no plant modification or interruption to operations.

It is unique in that a single piece of standalone hardware can be deployed to monitor any flow in any pipe size.

Our system is able to classify different flow regimes such as single phase flow,

stratified flow, wavy flow, slugging, plugging, bubbly flow, annular flow, mist and gas.

ALL OF THE ANSWERS, ALL OF THE TIME

NO DOWNTIME

NO DOWNTIME

Our flow surveillance system is non-intrusive. We do not break containment at any time and we do not use electronic equpiment in hazardous environments. All of the hardware can be deployed and commissioned on site with zero production downtime and zero interuption to ongoing operations.

The hardware we install in hazardous areas is not powered. We do not deploy any electronics equpiment outside of the safe area. Our sensor heads use Class I optical energy only, this is below the intrinsically safe threshold.

All of our deployed hardware is univerally interchangeable.

AVOIDABLE DEFERMENT

- Avoid production interruptions or deferment due to well testing. Continual real time flow surveillance reduces or eliminates the need for well testing

- Minimal setup time, the equipment is simple and easy to use with minimal installation time

- No contact metering means no process or flow interruptions.

OPTIMISATION GAINS

- Understand the network effects of hydrocarbon gathering systems, understand how wells are competing

- By standardising your surveillance hardware across your assets you can seamlessly transfer lessons learnt

- Deeper insight leads to superior reservoir drainage and injection modelling, improved optimisation and better financial forecasting

HARDWARE

Our monitoring technology represents a new paradigm for measuring complex flow parameters and fluid properties. Our universal multiplexed sensor technology means the solution is less expensive, more flexible and scalable.

The hardware is entirely non-intrusive, non-invasive and is intrinsically safe (OP-IS). The sensor heads are compact and require no electrical power to operate, allowing it to be deployed without minimal disruption or risk.

Our system measures nanoscale optical variances on the external surface of a pipe wall, from this our algorithm is able to determine what is happening inside the pipe including complex fluid behaviours and transient conditions such as wavy flow, slugging or elongated bubbles.

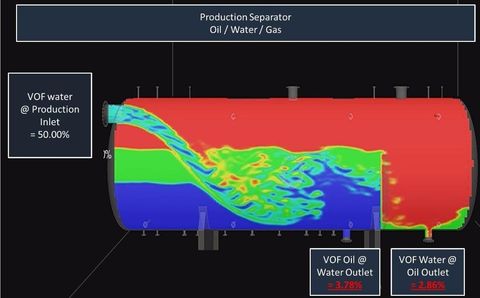

SOFTWARE

Our software delivers insight into flow parameters and fluid properties ahead of fluid arrival and eliminates the assumptions and guesswork.

This can transform the efficiency, throughput and operational performance of downstream facilities.

For example by observing the flow conditions upstream at the well site with unprecedented granularity we are able to simulate separator conditions ahead of fluid arrival.